Maximizing Checking Precision With Secured Examination Units in Electronic Advancement Processes

Protected test units have emerged as a vital device in enhancing the precision of testing treatments for digital parts and gadgets. The application of secured test units extends beyond simple insulation, providing a myriad of benefits that contribute to the total high quality and efficiency of screening outcomes.

Importance of Protected Test Rooms

Shielded units give a controlled testing atmosphere by protecting against electromagnetic interference (EMI) from external sources that can jeopardize the stability of digital screening treatments. By consisting of the electro-magnetic signals within the unit, shielded test units aid preserve the uniformity and repeatability of test outcomes, ultimately enhancing the total top quality of electronic growth processes.

Furthermore, protected examination units contribute to meeting regulatory criteria and compliance demands in the electronic devices sector. In essence, the significance of shielded examination rooms exists in their capacity to protect the precision and integrity of electronic advancement processes through the production of a regulated and interference-free testing environment.

Kinds of Shielded Examination Enclosures

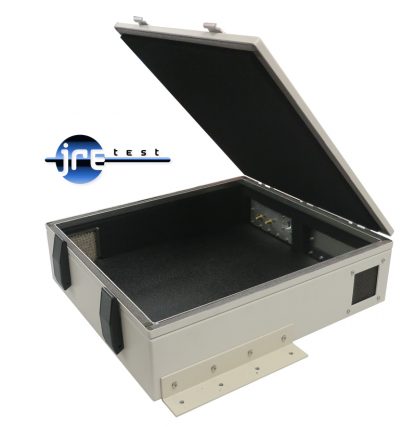

Various configurations of shielded test enclosures provide to varied testing requirements and specs in digital advancement procedures. One typical type is the benchtop protected test unit, which is ideal and portable for evaluating tiny electronic tools or parts. These enclosures offer a secured setting that prevents exterior disturbance throughout screening, making sure precise outcomes. Another kind is the rack-mounted secured examination unit, which is created to suit typical tools shelfs. This kind of unit is ideal for bigger testing arrangements where multiple devices need to be examined concurrently. Furthermore, mobile shielded test enclosures supply adaptability for on-site screening or when movement is called for. These rooms are light-weight and very easy to carry, making them optimal for field testing or fixing electronic systems (faraday cage rochester). Generally, the selection of protected test room depends upon the details testing requirements, the size of the tools being checked, and the degree of movement needed in the electronic growth procedure.

Benefits of Using Shielded Rooms

Enhancing electro-magnetic compatibility and making certain trusted examination outcomes, shielded rooms play a vital function in maintaining the stability of electronic development procedures. Among the crucial advantages of utilizing shielded rooms is their capability to reduce electro-magnetic interference (EMI) from outside sources. By giving a controlled setting with marginal exterior interference, shielded enclosures make it possible for exact testing of electronic tools without the risk of false results triggered by undesirable electromagnetic signals.

Moreover, secured rooms supply a high degree of safety and security by avoiding delicate details from dripping out and unauthorized signals from getting in the testing environment. When testing proprietary or private electronic components that call for a safe testing environment., this feature is especially essential.

In addition, secured find out here rooms help in conforming with regulatory requirements and accreditations by supplying a controlled screening environment that satisfies the needed electromagnetic compatibility (EMC) guidelines. This guarantees that the digital gadgets being examined will certainly satisfy the essential industry criteria for electromagnetic emissions and resistance, leading to smoother accreditation processes and quicker time-to-market for products.

Factors To Consider for Shielded Enclosure Choice

In the process of selecting shielded units for digital growth, mindful factor to consider of environmental aspects and particular needs is critical. The first consideration when choosing a shielded unit is the material used for its building and construction.

One more vital variable to consider is the degree of protecting required for the screening setting. High-frequency applications might require enclosures with premium electromagnetic interference (EMI) shielding capacities to stop signal disturbance and make sure precise examination results. The access attributes of the enclosure, such as doors, ports, and panels, need to align with the screening demands to promote practical access to the tools under test.

Lastly, the transportability and scalability of the protected unit should be reviewed to make sure flexibility check that in accommodating future screening requirements and possible reconfigurations. By carefully evaluating these factors to consider, electronic advancement procedures can make best use of testing accuracy and efficiency with the appropriate protected unit option.

Assimilation of Shielded Enclosures in Screening

The seamless assimilation of protected enclosures into screening treatments is important for making sure exact and dependable electronic growth procedures. Protected rooms play a vital duty in minimizing external disturbance throughout testing, therefore enhancing the precision of results. When integrating secured enclosures right into screening settings, it is necessary to consider variables such as the dimension of the room, the type of protecting material used, and the particular testing requirements of the electronic components being reviewed.

One secret element of incorporating secured units into testing is making sure correct connectivity within the enclosure. This consists of developing safe and secure links for source of power, data transfer, and monitoring tools to efficiently carry out tests while keeping the shielding effectiveness of the enclosure. In addition, executing proper air flow and cooling down systems within the room is important to prevent getting too hot see here now of electronic parts during testing procedures.

Conclusion

Finally, the use of protected test rooms in digital advancement procedures is important for making best use of testing precision. Different sorts of shielded rooms use different advantages, and mindful consideration must be provided to choosing one of the most suitable one for details testing requirements. Incorporating protected units into the testing procedure can significantly boost the dependability and effectiveness of electronic testing treatments.

Shielded enclosures supply a regulated testing atmosphere by protecting against electromagnetic interference (EMI) from external resources that can compromise the integrity of electronic screening procedures - rf chamber rochester. By including the electromagnetic signals within the room, secured examination units aid maintain the uniformity and repeatability of examination end results, ultimately enhancing the overall high quality of digital growth procedures

When incorporating protected enclosures into testing atmospheres, it is essential to consider factors such as the size of the unit, the kind of securing material utilized, and the particular testing needs of the electronic components being evaluated.

One secret aspect of incorporating secured units right into testing is ensuring appropriate connectivity within the enclosure. Incorporating secured units right into the screening process can substantially enhance the dependability and efficiency of electronic screening treatments.